Why Choose Rotational Molding?

Rotomolded Parts Are Customizable & Durable

Rotational molding, or rotomolding, is the process of heating and spinning plastic resin in a mold to achieve a hollow plastic shape. The technique allows rotomolders such as Michiana Rotational Molding to deliver custom products for use in a variety of industries.

Benefits of Rotomolding

Flexibility with Shape

Corrosion Resistance

Less Reliant on Aluminum

Lighter Weight

Easy to Add Secondary Parts

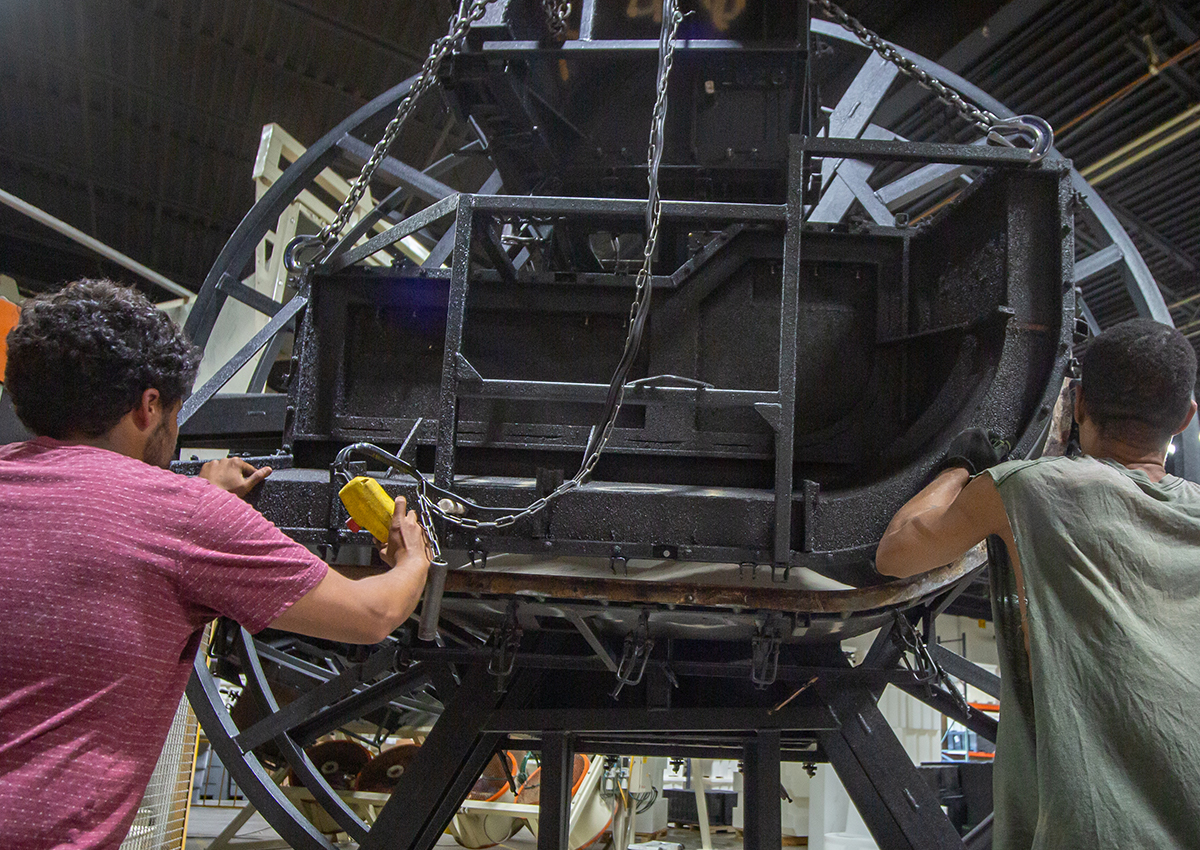

The Rotomolding Process

The rotomolding process is a simple yet effective way to produce consistent, quality parts. At Michiana Rotational Molding, our process enables us to provide you with customized parts and one-of-a-kind service.

Design & Feasibility

You will work with our design team to engineer your product and we’ll perform a feasibility check to ensure our process is the best fit for your unique needs.

Mold Production

The design is then converted and a mold is made in our in-house mold shop. Existing molds can also be repaired.

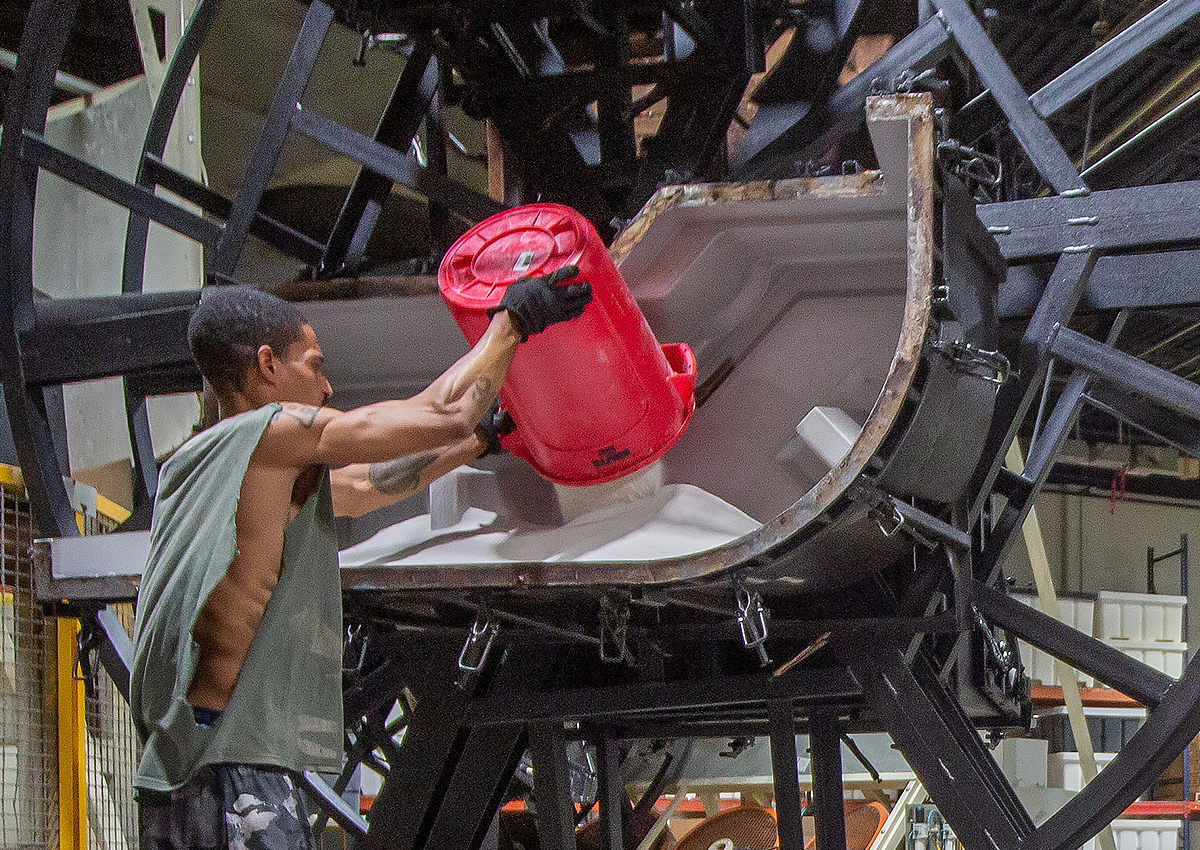

Production & Finishing

Standard or customized resin colors are used in the rotational molding process to produce your product. After released from the mold, the product goes through secondary finishing, assembly, and quality review before being packaged and shipped.

Contact us today to learn how we can solve your rotomolding challenges!